Alloys

Non-Ferrous Alloys

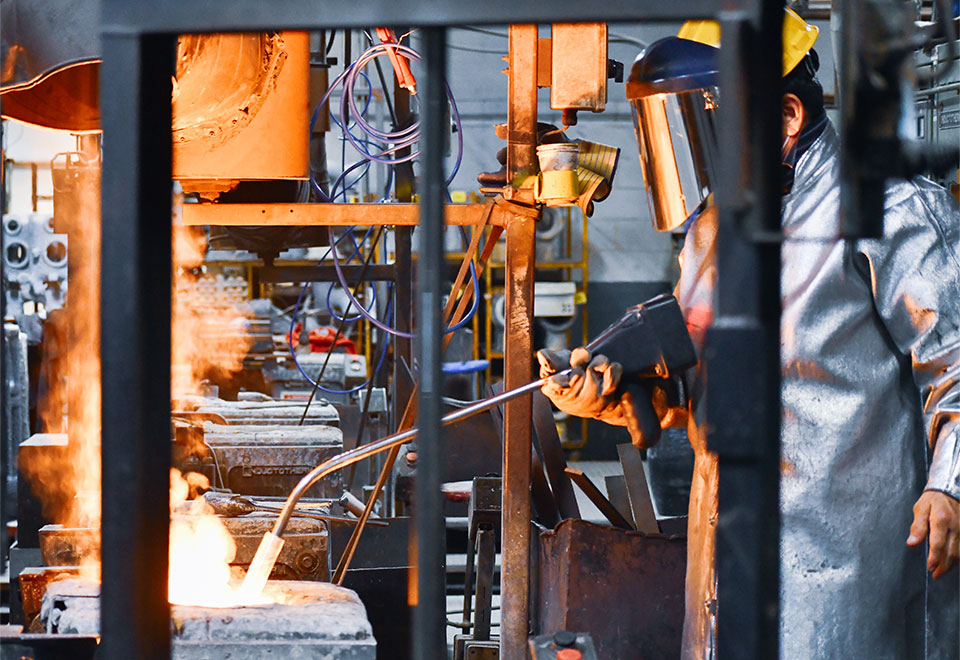

New tooling + New alloy = Alphacasting solution

Because of its capacity to produce non-ferrous alloys, that meet high performance and output specifications, Alphacasting is chosen by Hi-tech industries.

Our clients’ requirements are very important to us. We adhere to rigorous standards while keeping in mind the critical elevated mechanical properties of some alloys. We take the right precautions to meet our clients’ expectations and needs.

Ferrous Alloys

We rise to any challenge

By serving several types of industries, we are constantly evolving and regularly demonstrating versatility.

We cast more than 120 different alloys including all carbon steels, stainless 300 & 400 series, 15-5 PH, 17-4 PH, aluminum alloys, brass and bronze, in sizes varying from fractions of an ounce to 35 lbs (from a few grams up to 15 kilograms).

Exotic Alloys

When quality meet quantity

In the field of precision investment casting, Alphacasting stands out with its high-level performance. Our company uses more than a hundred alloys, including nickel, bronze, aluminum and stainless steels.

We combine teamwork, meticulous quality control, production capacity, and the foundry's cutting-edge technology with the skills of our technicians and specialized engineers. Through this unique formula we join forces with our clients to make every project a success.

Investment casting metals

Explore your options and discover the right alloy for your components.

Discover Our Alloys

Aluminum Investment Casting

Corrosion resistance allied to the mechanical properties are the strength of Aluminum alloys.

They are roughly one-third as dense as steel with a higher strength to weight ratio.

300-Series Stainless Steels

The 300-series group of stainless steels is composed of 16-30% chromium and 6-35% nickel. Depending on the composition, the microstructure is mostly austenitic and thus unresponsive to heat treatment.

Carbon and Low-Alloy Steels

Carbon and low alloy steels are the backbone of the mechanical world. No other class of materials offers such a wide a range of mechanical properties while also being economical.

400-Series Stainless Steels

The 400-series group of stainless steels contains 11-27% chromium, approximately 1% carbon, and a maximum of 2.5% nickel. Alphacasting produces grades of stainless-steel castings that mostly respond to heat treatment and can be supplied with a predominantly martensitic microstructure in a wide range of strengths and hardness.

Tool Steels

Alphacasting produces tools made of iron alloys containing 0.25-2.5% carbon with considerable amounts of tungsten, chromium, tungsten, vanadium, molybdenum, cobalt, and small amount of nickel, to get the desired combination of toughness, hardness, hardenability and wear resistance.

Titanium

There is so much to say about titanium, the wonder metal in our world. So, we created an entire page dedicated to its properties and uses.

We know metal alloy

We solve casting challenges.

Each customer has unique requirements to bring their metal application to life, and material selection is critical in product development.

Our melt technicians are devoted to custom mixing alloys to obtain a metallurgical product that is certified to respond to individual customer requirements.

Every heat is spectrographically tested to provide the correct chemistry. Mechanical properties are certified by in-house testing of separately cast tensile specimens.

We have what you need, and we are here to help. Whether you need to discuss alloy metallurgy or review required mechanical properties, we can help you select the investment casting alloy that’s right to meet the rigors of your specific application.

We want to hear from you!

New tooling + New alloy = ALPHACASTING Solution